Pesticide residue testing ensures the safety of dietary supplements in a market expected to exceed $230 billion by 2027. Contaminants like pesticides, commonly used in agriculture, can pose serious health risks, including endocrine disruption, neurotoxicity, and cancer. Testing protects consumers, meets strict FDA and international standards, and helps manufacturers avoid penalties.

Key Points:

- Health Risks: Chronic exposure to pesticides can harm the nervous and endocrine systems, increase cancer risk, and affect vulnerable groups like children and pregnant women.

-

Testing Methods:

- LC-MS: Detects non-volatile, heat-sensitive pesticides.

- GC-MS/MS: Best for volatile pesticides.

- Immunoassays: Quick, cost-effective initial screening.

-

Regulations:

- FDA requires safety verification, threshold monitoring, and adherence to Good Manufacturing Practices (GMP).

- Certifications like NSF/ANSI 173 and international standards (e.g., EU’s Maximum Residue Levels) ensure compliance.

- Industry Example: MASI Longevity Science uses advanced testing, Swiss lab verification, and supply chain tracking to meet global safety standards.

Why It’s Important for You:

If you use supplements, knowing they’re tested for pesticide residues ensures your health and safety. For manufacturers, rigorous testing builds trust and complies with regulations. This is essential as technology advances and safety standards rise.

Why Third-Party Certification Is a Good Investment For Supplement Brands

Testing Methods for Pesticide Residues

Testing for pesticide residues involves using advanced analytical tools to ensure the safety of supplements. Each method is tailored to detect specific pesticide types, offering varying levels of precision and sensitivity.

LC-MS Analysis

Liquid Chromatography-Mass Spectrometry (LC-MS) is ideal for identifying non-volatile and heat-sensitive pesticides. It operates with a liquid mobile phase, making it especially effective for detecting water-soluble compounds [5]. Known for its high sensitivity and broad dynamic range, LC-MS also speeds up testing with simpler sample preparation, balancing efficiency and accuracy [7].

GC-MS/MS Testing

Gas Chromatography-Mass Spectrometry (GC-MS/MS) excels in detecting volatile pesticide residues in dietary supplements. While it requires additional preparation for certain compounds, its precision is unmatched for volatile substances [5].

| Feature | GC-MS/MS Advantage |

|---|---|

| Matrix Interference | Reduces signal interference from complex ingredients [6] |

| Compound Detection | Best suited for volatile pesticides and chemical residues [5] |

Immunoassay Screening

Immunoassay methods, like Enzyme-Linked Immunosorbent Assay (ELISA), provide a quick and cost-effective way to screen for specific pesticides [9].

"In comparison with classical analytical methods, ELISA methods offer the possibility of highly sensitive, relatively rapid, and cost-effective measurements." - Gilvanda Silva Nunes, TrAC Trends in Analytical Chemistry [9]

Recent advancements, such as nano-modified immunoassays, have improved sensitivity, making these tests more dependable for large-scale applications [8]. Immunoassays are often used as initial screening tools before more detailed chromatographic analysis.

The choice of testing method depends on several factors, including:

- The complexity of the sample matrix

- Sensitivity requirements to meet regulatory standards

- The specific range of pesticide residues being targeted [10]

Health Risks from Pesticide Residues

Thorough testing methods are absolutely crucial because even trace amounts of pesticide residues can pose serious long-term health risks. Consuming supplements that contain these residues regularly can have profound health implications, highlighting the need for stringent safety standards.

Long-term Health Effects

Research into the health impacts of pesticide residues has uncovered several concerning effects:

| Health System | Potential Effects |

|---|---|

| Nervous System | Increased risk of neurodegenerative disorders [4] |

| Endocrine System | Hormonal imbalances and disruptions [3] |

| Cellular Function | Oxidative stress and interference with metabolism [12] |

| Cancer Risk | Higher likelihood of hormone-related cancers [4] |

One notable study involving 30,000 women found a direct link between exposure to organophosphate pesticides and a greater risk of hormone-related cancers, such as breast, thyroid, and ovarian cancer [4]. These findings emphasize why rigorous testing is non-negotiable in supplement production. Certain groups face even greater risks, as outlined below.

High-Risk Groups

A European biomonitoring study conducted across five countries has revealed that specific populations are especially vulnerable to elevated pesticide levels [11].

Groups at Greater Risk:

- Children and pregnant women: Children, in particular, are at higher risk of developmental issues, including ADHD and autism, due to higher pesticide concentrations [11] [4].

- Individuals with chronic conditions: Those managing ongoing health issues are more susceptible to the adverse effects of pesticide exposure [13].

In a large-scale biomonitoring effort, 84% of participants showed detectable levels of pesticides, with children consistently exhibiting the highest concentrations [11].

Michael Hansen, Senior Scientist at Consumer Reports, explains: "The way the EPA assesses pesticide risk doesn't reflect cutting-edge science and can't account for all the ways the chemicals might affect people's health, especially given that people are often exposed to multiple pesticides at a time" [14].

Testing Rules and Standards

Ensuring the safety of dietary supplements goes beyond detailed testing techniques - it also requires adherence to strict regulatory and certification standards. These standards include mandatory government requirements and optional third-party certifications, all designed to uphold product safety and consumer trust.

FDA Requirements

The FDA oversees dietary supplements under the Federal Food, Drug, and Cosmetic Act (FFDCA) [15]. Manufacturers are required to meet specific guidelines, including:

| Requirement | Description | Compliance |

|---|---|---|

| Safety Verification | Ingredients are considered unsafe until proven safe | Food additive petition or FDA review |

| Threshold Monitoring | Testing to ensure substances remain below regulatory thresholds | Verification at de minimis levels |

| Manufacturing Practice | Adhering to Good Manufacturing Practice (GMP) standards | Bi-annual facility inspections |

Before receiving FDA clearance, manufacturers must demonstrate that their products are safe for their intended use [15]. This rigorous process lays the groundwork for further third-party validations.

Independent Certifications

NSF/ANSI 173 is the only American National Standard for dietary supplements [1]. The certification process involves:

- Bi-annual inspections of manufacturing facilities

- Verification of product formulations and label accuracy

- Regular audits of manufacturing protocols

- Annual product testing to ensure compliance

"The new testing requirements fill an important gap. Pesticides lacking residue limits are currently held to a 'precautionary zero tolerance,' which has moved closer and closer to zero over time as analytical testing methodologies have advanced. NSF's evidence-driven approach minimizes reliance on zero tolerance while remaining protective of public health and safety."

- Rebecca Adams, NSF research toxicologist [1]

Other certifications, like the Clean Label Project and Glyphosate Residue Free certification, evaluate products based on additional safety benchmarks, including California's Proposition 65 limits [16][17].

International Testing Standards

Globally, the European Union (EU) has established stringent testing standards that set an example for safety protocols. Key elements of EU regulations include:

- A Maximum Residue Level (MRL) of 0.01 mg/kg for pesticides not explicitly listed [18]

- Standards covering 315 fresh products and their processed forms [19]

- Oversight of approximately 1,100 pesticides used worldwide [19]

EU monitoring data reveals that 96.3% of over 110,000 food samples tested fell within acceptable MRL limits, with only 2.2% categorized as non-compliant after accounting for measurement uncertainty [20]. These benchmarks often guide U.S. manufacturers aiming to demonstrate their dedication to safety and quality.

These rigorous standards form the foundation of the quality assurance protocols used by MASI Longevity Science.

sbb-itb-4f17e23

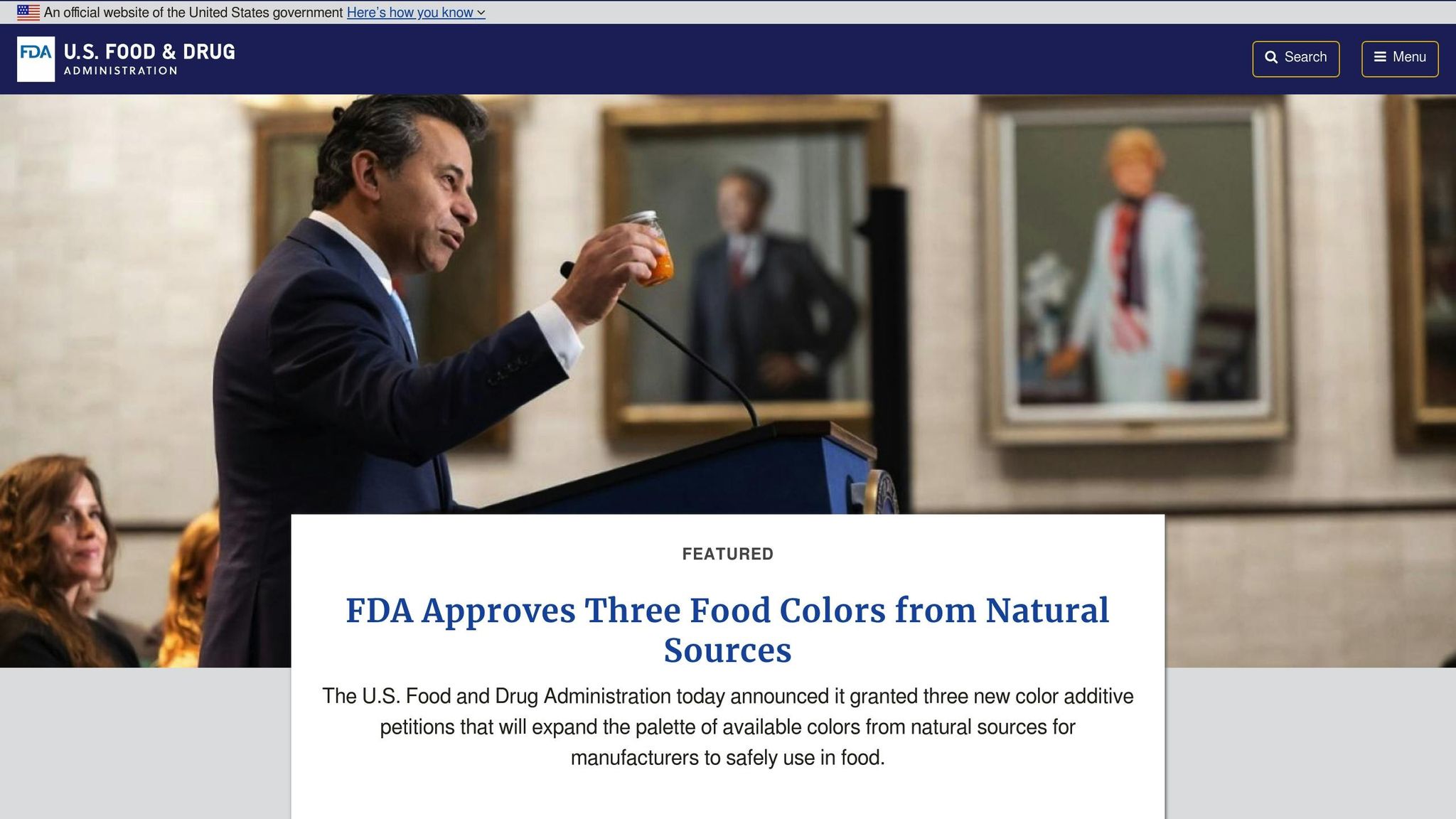

MASI Longevity Science Quality Testing

MASI Longevity Science employs a thorough quality control system, focusing on pesticide residue testing and raw material verification. Below, we break down the key components of their raw material protocols, independent lab testing, and supply chain monitoring.

Raw Material Standards

MASI's raw material standards adhere to NSF/ANSI 173 guidelines, with additional safety measures for enhanced quality assurance. At their German manufacturing facilities, a systematic testing process is implemented:

| Testing Phase | Verification Process | Quality Parameters |

|---|---|---|

| Pre-Import | Multi-residue screening | Over 800 pesticide compounds |

| Arrival Testing | Advanced GC-MS/MS and LC-MS/MS methods | Chemical-specific limits for 185 pesticides |

| Production | Ongoing monitoring | Verification of environmental controls |

Instead of testing blended ingredients, MASI performs individual assessments on each botanical component. This ensures precise identification of pesticide residues, focusing on critical substances like glyphosate, haloxyfop, and post-harvest fumigants such as ethylene oxide.

Swiss Laboratory Testing

To further ensure quality, MASI collaborates with independent Swiss laboratories for additional analysis. Their testing program includes:

- Multi-Residue Analysis: Using cutting-edge GC-MS/MS and LC-MS/MS technologies, the labs screen for around 800 pesticide residues in a single test.

- Specialized Testing: Tailored methods address specific compounds, particularly in botanical extracts, with limits adjusted according to USP <565> standards.

Supply Chain Tracking

MASI employs a sophisticated supply chain monitoring system to uphold product integrity at every stage of production. Key elements include:

- Origin Verification and Traceability: Products are tracked from their source to the final product using unique batch identifiers.

- Digital Documentation: Automated systems record test results and certifications for seamless tracking.

- Real-Time Monitoring: Environmental conditions during storage and transport are continuously monitored to ensure compliance.

This meticulous approach enables MASI to consistently meet or exceed FDA and international regulatory standards for pesticide residue limits, ensuring the highest quality across their product line.

Conclusion

Pesticide residue testing plays a crucial role in a supplement market expected to surpass $230 billion by 2027 [2]. These stringent testing practices are at the core of MASI Longevity Science's commitment to quality, ensuring consumer safety, meeting regulatory demands, and fostering trust in their brand.

MASI Longevity Science employs a meticulous approach that includes independent Swiss lab testing, thorough evaluations of individual ingredients, and constant monitoring of their supply chain. This detailed process ensures that every batch adheres to the highest standards, consistently aligning with FDA and global regulatory requirements.

For both manufacturers and consumers, advancements in testing methods reflect a steadfast dedication to quality control. These efforts are essential for protecting public health and maintaining confidence in the industry. As technology continues to improve, the focus on safety only grows stronger, raising the bar for supplement quality assurance.

FAQs

Why is it important to test dietary supplements for pesticide residues, and what are the potential health risks?

Testing dietary supplements for pesticide residues plays a crucial role in ensuring they are safe to consume and comply with regulations. Even trace amounts of pesticides can lead to serious health concerns over time, such as a higher risk of cancer, hormonal imbalances, and nervous system damage.

Thorough testing helps manufacturers shield consumers from harmful chemicals and strengthens confidence in their products' quality and safety. With the growing popularity of dietary supplements, maintaining their purity and safety through proper testing is essential to support long-term health.

How do LC-MS, GC-MS/MS, and immunoassay methods differ in detecting pesticide residues in supplements?

Analysis Methods for Pesticide Residues

LC-MS (Liquid Chromatography-Mass Spectrometry) is a powerful tool for detecting a broad spectrum of pesticide residues, even in complex substances or those with high boiling points. This method offers outstanding sensitivity and precision, but it comes with higher costs and requires experienced operators to manage the equipment effectively.

GC-MS/MS (Gas Chromatography-Tandem Mass Spectrometry) excels at analyzing pesticides that are both volatile and thermally stable. While this method produces highly accurate results, it is not suitable for testing non-volatile or thermally unstable compounds.

Immunoassays, such as ELISA, are a quicker and more affordable option for initial screenings. However, they fall short in sensitivity and specificity compared to LC-MS or GC-MS/MS, making them less dependable for confirmatory testing.

Each of these methods has its advantages, and the right choice depends on the specific properties of the pesticide residues being examined.

How do international regulations, like those in the EU, impact pesticide testing standards for dietary supplements?

International regulations, particularly those set by the European Union (EU), significantly influence the standards for pesticide residue testing in dietary supplements. The EU enforces strict Maximum Residue Levels (MRLs) for pesticides in food, which also apply to supplements categorized as food products. These rules aim to safeguard consumer health by ensuring pesticide residues remain within scientifically established safe limits.

To uphold safety and uniformity, the EU has implemented a standardized framework for testing methods across its member countries. This approach ensures that dietary supplements consistently meet stringent safety and quality requirements. On a broader scale, global organizations have revised their testing protocols to align with these regulations, allowing for specific permissible pesticide levels rather than adopting a zero-tolerance policy. By following these guidelines, manufacturers can produce supplements that are not only safe but also meet international compliance standards.